In telangana andhra pradesh and it surroundings states we have constructed many industrial floorings and carried out vacuum dewatering concrete floorings groove cutting as well as other civil works.

Vacuum dewatering of concrete flooring ppt.

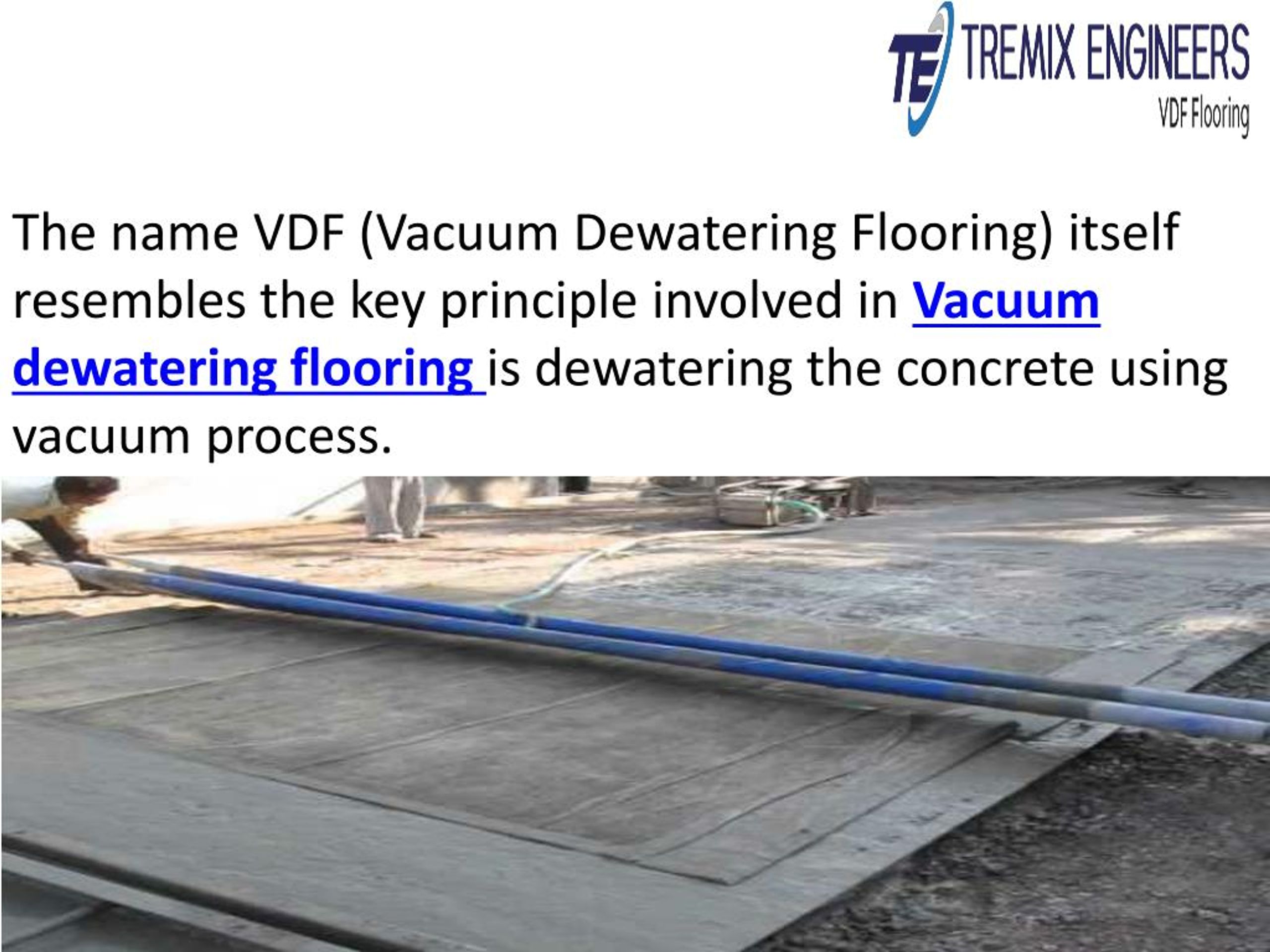

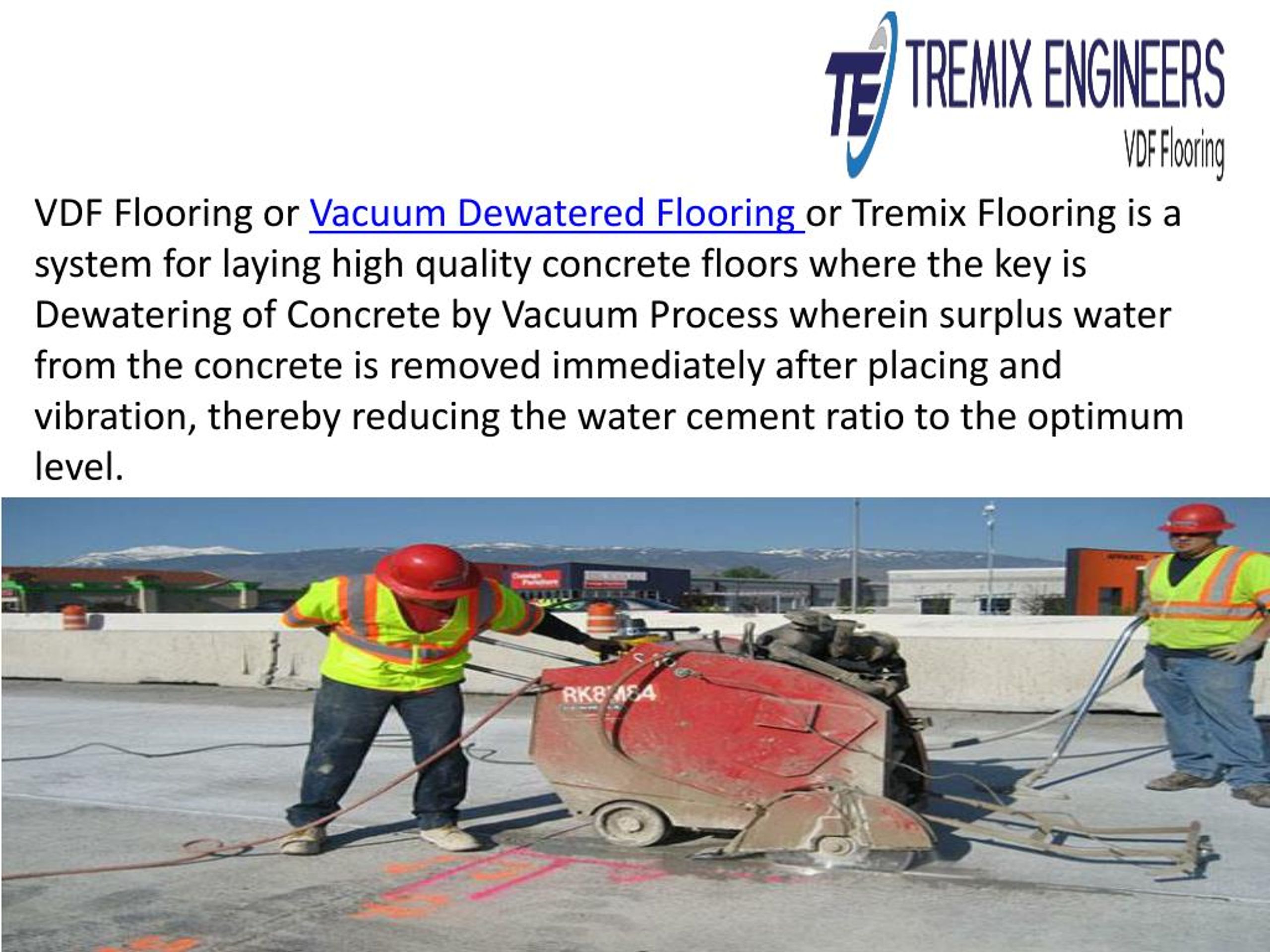

The key to the use of this method is the dewatering of concrete by vacuum process.

This process was introduced in india by aquarius technologies in 1987.

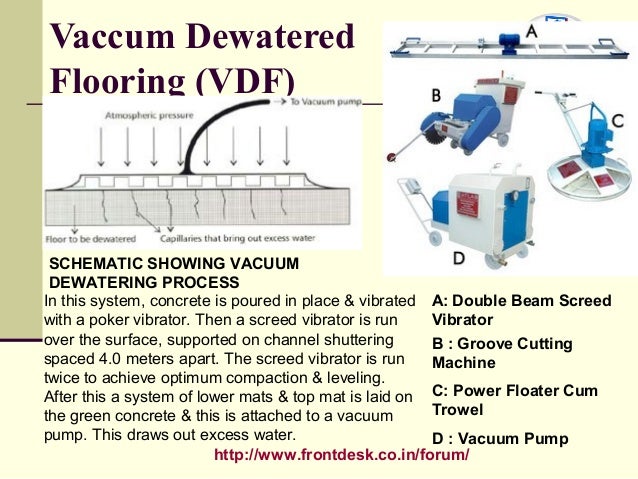

Consideration in concrete dewatering the vacuum is applied through the porous mats connected to the vacuum pump.

The vacuum dewatered vd flooring method is a system for laying high quality concrete floors with superior cost effectiveness.

The key to the use of this method is the dewatering of concrete by vacuum process.

Category science technology.

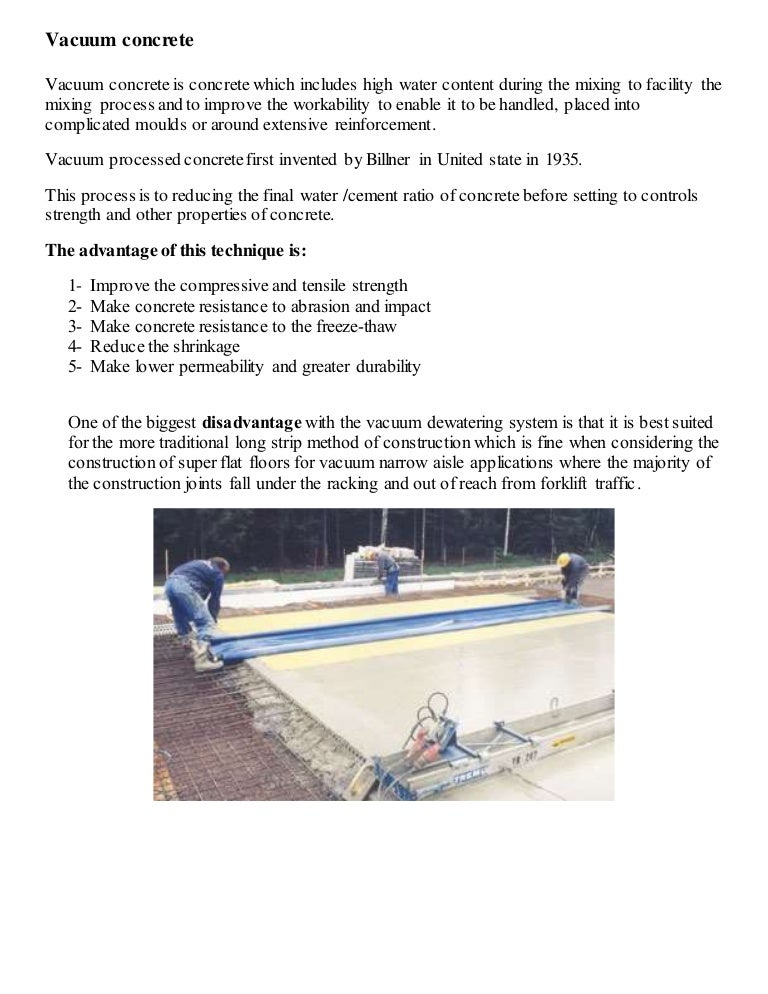

The vacuum dewatering results in coarse aggregate in the fresh mix being drawn to the top surface a further contributing factor in achieving wear resistant concrete surfaces the surface of vacuum treated concrete is free of pitting an important consideration for abrasion resistance and the possible exposure to a continuous flow of liquid over the member.

The vacuum dewatering process basically improves strength durability and other properties of concrete by reducing the water cement ratio immediately after the mix is placed usually in floors and other flatwork.

Surplus water from the concrete is removed immediately after placing and vibration.

This system is called vacuum dewatered floors vdf the vacuum dewatered vd flooring method is a system for laying high quality concrete floors with superior cost effectiveness.

Trimix flooring machine and vacuum dewatering system we are the leading manufacturer and exporter of a premium quality range of groove cutting machines concrete mixer machine concrete power trowel trimix flooring machine etc these products are designed and manufactured by our experts using excellent quality components with the help of advanced technology.

These vacuum dewatered flooring services are executed under the guidance of our skilled and experienced professionals using advanced machines and tools.

Surplus water from the concrete is removed immediately after placing and vibration reducing the watercement ratio to an optimum level.

The vacuum dewatering results in coarse aggregate in the fresh mix being drawn to the top surface a further contributing factor in achieving wear resistant concrete surfaces the surface of vacuum.